Supply Chain

PRO’s Supply Chain Team of experts have rich knowledge and experience on supply chain processes, from initial forecasting to customer delivery. With ongoing supply constraints, increased premiums on supplies, and shifting customer preferences, companies face turbulent waters when trying to stabilize or grow their supply chains. Understanding how to build the right quantity, at the right time, at the right cost, in the right location is key to building controls to steer towards the optimal plan.

PRO has extensive experience in helping clients address these levers to gain control over their supply chain. Whether the goal is to better forecast to meet Service Level Agreements, optimize production & logistics planning, maximize production capabilities, or migrate production facilities on/offshore, PRO experts will determine exactly where your current-state supply chain processes lie and help strategically implement process improvements to greatly accelerate overall process advancements.

Functional Areas

-

Market Forecasting

-

Demand Planning

-

Inventory Planning

-

Supply Planning

-

Customer Fulfillment Planning

-

Factory / Production Planning

-

Supplier Management

-

Logistics Management

-

Carrier Management

- Market Forecasting

- Demand Planning

- Inventory Planning

- Supply Planning

- Customer Fulfillment Planning

- Factory / Production Planning

- Supplier Management

- Logistics Management

- Carrier Management

“With any other consultancy, it would have taken three times as long and cost twice as much. Also, with PRO, the depth and consistency of quality output surpasses any other firm for what PRO does.”

Senior Director, Supply Chain

A Project with PRO…

Could Generate Similar Benefits

By Identifying and Addressing Key Operational Issues

Streamline & Standardize Manual Processes (26)

Improve Inbound & Internal Data Quality (18)

Improve Forecasting & Planning (12)

Enhance Staff Tools & Trainings (11)

Roles, Responsibilities & Management Tools (8)

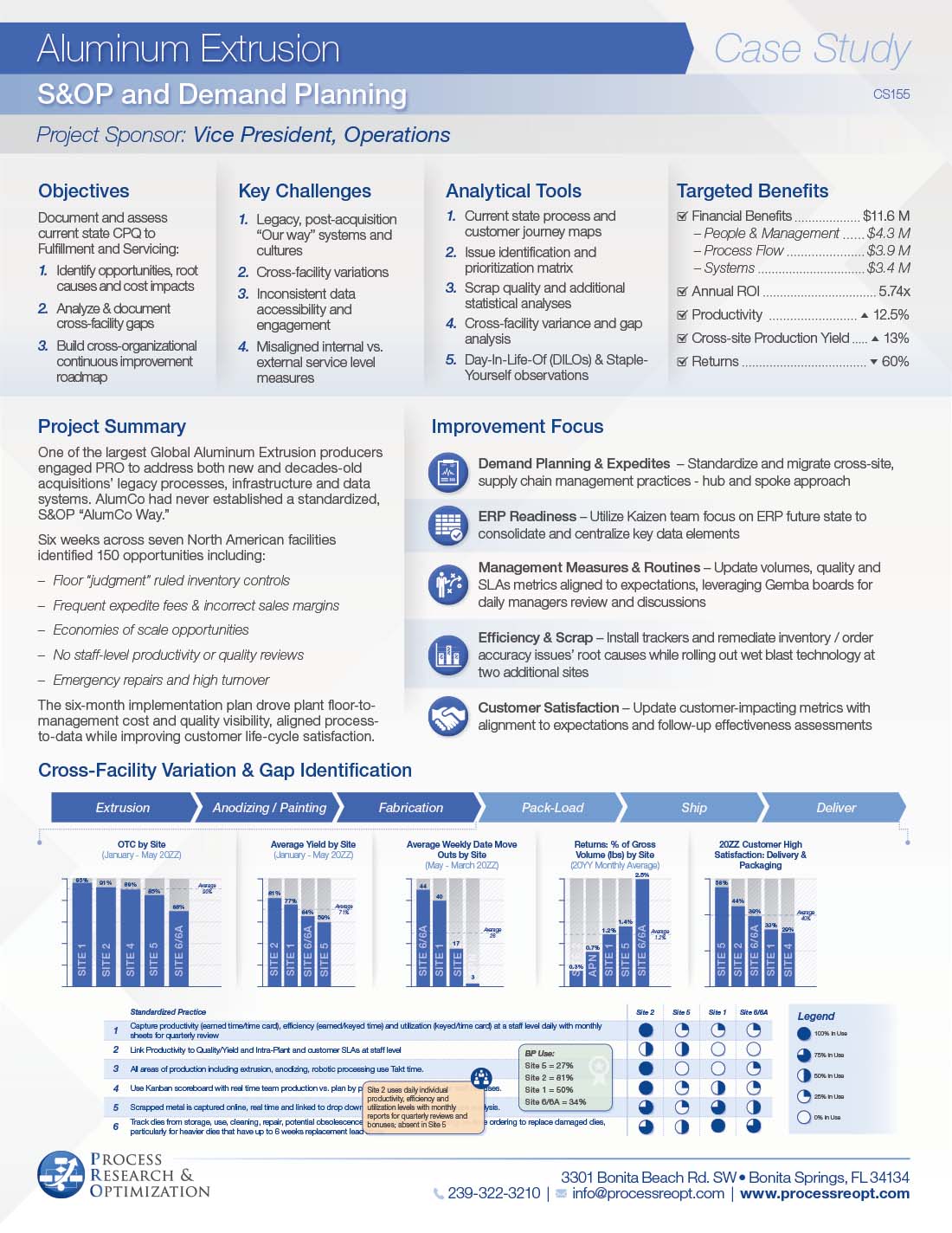

Case Study

One of the largest Global Aluminum Extrusion producers engaged PRO to address both new and decades-old acquisitions’ legacy processes, infrastructure and data systems. AlumCo had never established a standardized, S&OP “AlumCo Way.”

The six-month implementation plan drove plant floor-to-management cost and quality visibility, aligned process-to-data while improving customer life cycle satisfaction.

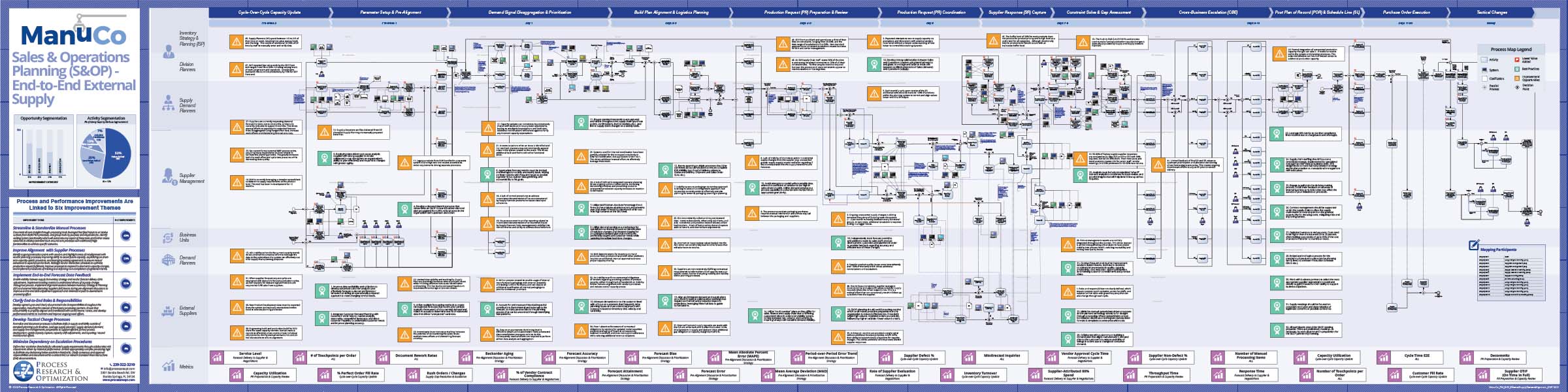

S&OP Process

End-to-End S&OP Process follow, outlining sample processes improvements. This process map covers key stages in the S&OP process, such as:

- Cycle-Over-Cycle Capacity Update

- Demand Signal Disaggregation & Prioritization

- Build Plan Alignment & Logistics Planning

- Production Request Preparation and Review

- Cycle-Over-Cycle Capacity Update

- Demand Signal Disaggregation & Prioritization

- Build Plan Alignment & Logistics Planning

- Production Request Preparation and Review